<< Intro. >>

Today the power semiconductor packages face the paradigm shift.

The shift is driven by the semiconductor material transition from silicon to the wide-band-gap(WBG) material such as Silicon-Carbide(SiC) and Gallium-Nitride(GaN).

It affects the design and process of overall system.

One of changing perspectives is the die-attachment material.

Conventionally Tin-based solder preform is the common choice for its easy use and reliability.

However, the thermal conditions will be drastically harsh with WGB devices, especially that of SiC.

Instead of solder, silver(Ag) sintering paste system will be the next generation die-attachment material.

<< What We Offer – PureFit >>

The aluminum-graphite composite material could go along with surface finish.

We have offered the plated fixtures for soldering process.

Now, SI Precision and our partner are developing the engineering-plastic coating for fixtures.

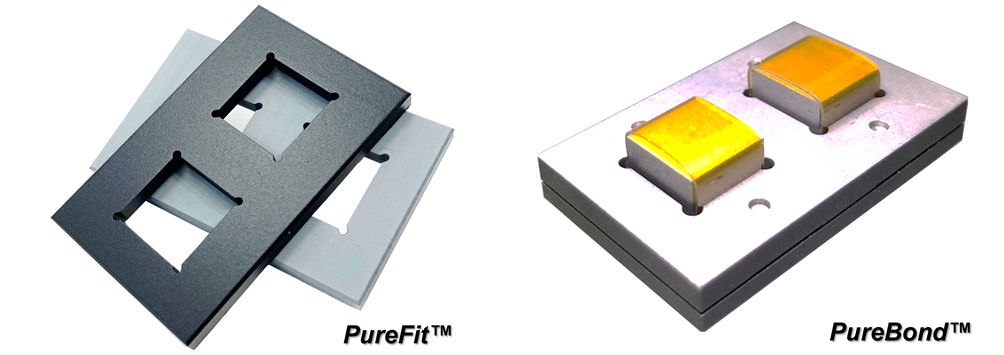

It will be called “PureFit” *Trademark is under application

PureFit insists aluminum-graphite composite fixtures coated with engineering-plastic.

Coating significantly reduces the amount of carbon dusts, isolates fixture surface from oxygen and chemicals, and resists compound binder in Ag sintering paste system.

Ag sintering specimen using PureFit.

Extra amount of sintering paste between bare devices and base plate for the testing purpose.

Sintering quality is poor at the edge in gray. This is due to the base plate curvature reducing the contact with fixture. In the reality, Ag paste is screened only beneath the devices.

Ag paste residue does not remain on fixture surface. The residue is resisted by engineering plastic coating.

Coating has survived several thermal treatment.

1.320℃ x 300min, no pressure-loading

2.275℃ x 60min, 10MPa loading, N2 chamber

<< What We Offer – PureBond >>

Ag sintering paste system sometimes need the pressure assist.

There are key process factors required for tooling: gives no damage to device surface and provides uniform pressure load per device area.

SI Precision has rich experience in adding mechanical gimmick to the fixture.

We call it “PureBond” *Trademark is under application

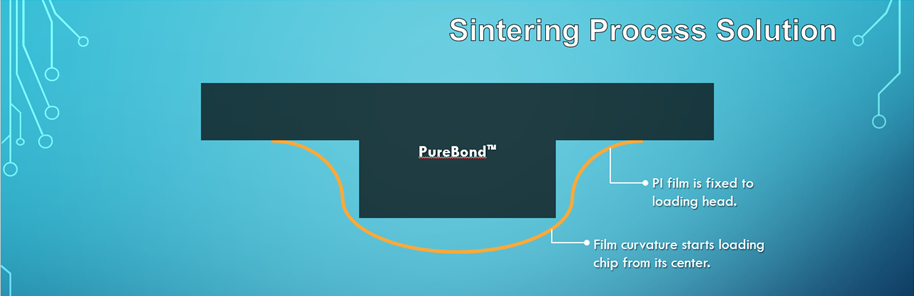

PureBond is the graphite or aluminum-graphite fixture in which film of engineering plastic, such as polyamid, is fixed.

The idea is to the convex curvature gives the pressure starting the center of device.

Film thickness is ideal to absorb the surface roughness of device and fixture, while its soft texture reduces the risk of damage in devices.